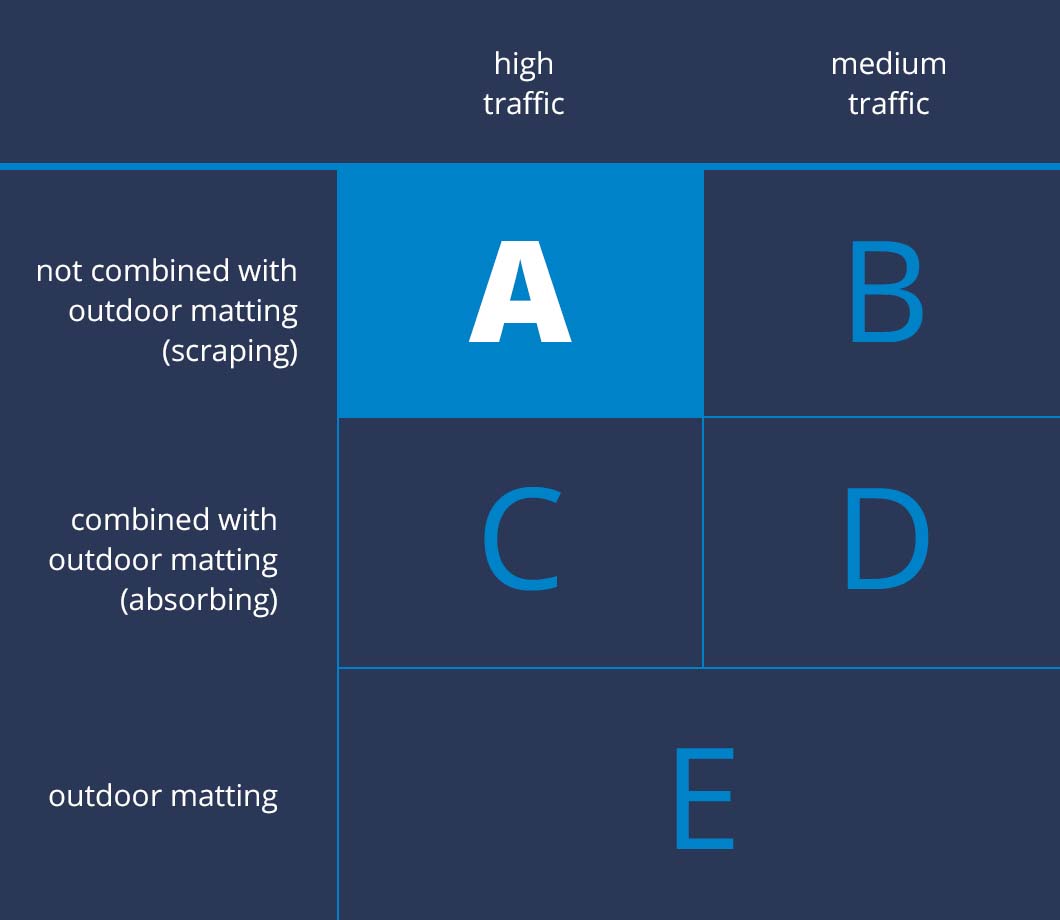

Rinos has a mat for every entrance. In high-traffic locations like shopping centres, large hotels, museums and healthcare centres, or in medium traffic locations, such as showrooms, offices and houses. Choosing the right entrance mat means answering two important questions:

- How much traffic passes through the entrance?

- And does the entrance have an outside mat?

We manufacture walk-off carpeting for every situation. For high and medium traffic locations. And also for areas where there is a lot of walking in and out by people wearing safety shoes and shoes with hard, profiled soles.