Since 1925

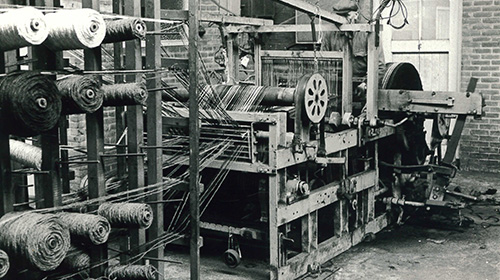

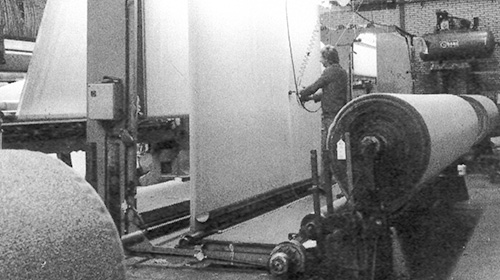

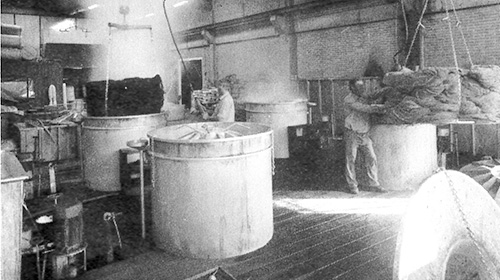

Rinos has developed and produced coir entrance mats and walk-off carpets since 1925. As a specialist, we supply our mats worldwide to wholesalers, distributors and leading carpet brands, who distribute our products under their own brand names to offices, shops, hotels, museums, hospitals and commercial interior decorators.

7 reasons for choosing Rinos

For some, our knowledge and experience are decisive, for others it’s our logistics, or private label approach. There are seven important reasons to choose Rinos.

- knowledge and experience: a century of craftsmanship

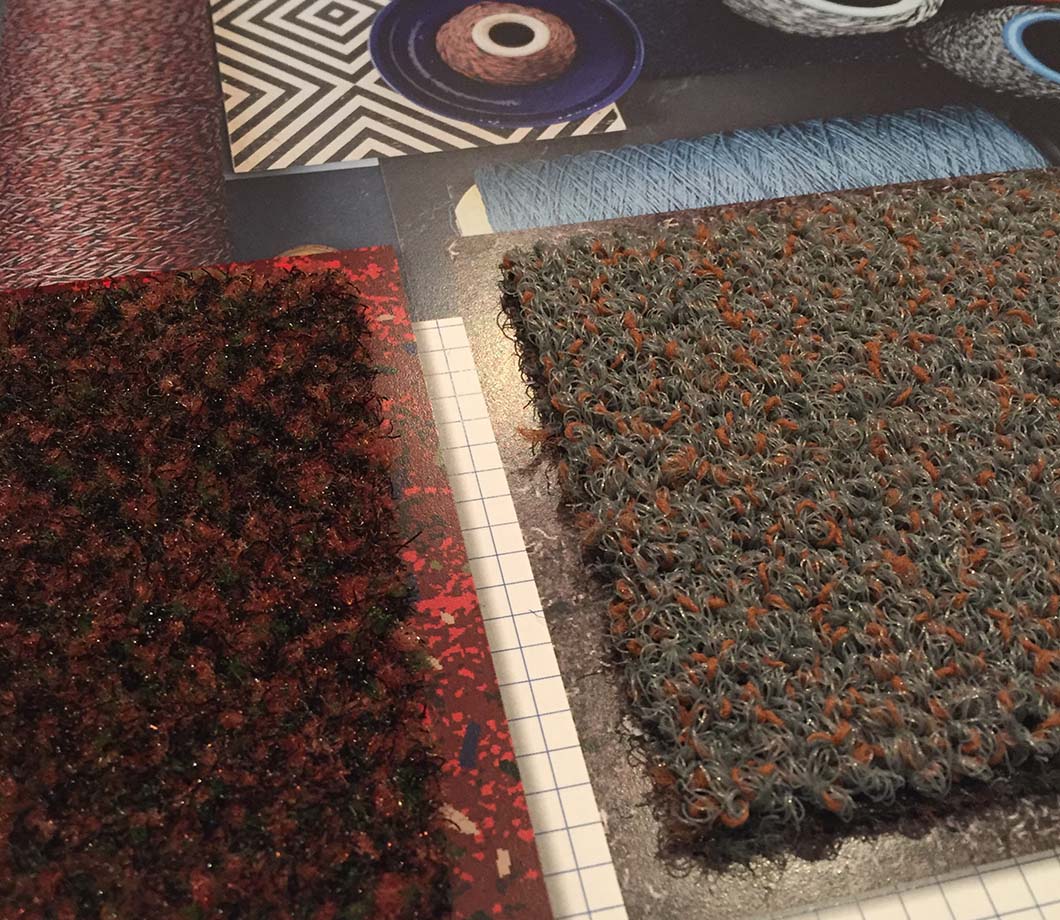

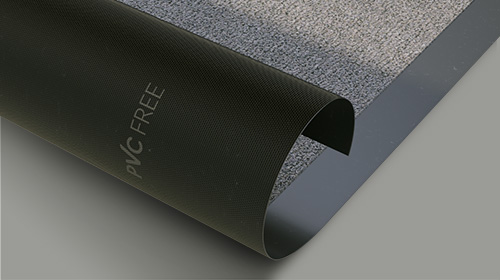

- branded features: unique product innovations

- marketing & promotion: support for distribution brands

- logistics service: a deal is a deal

- private label service: your own mat designs

- sustainable: product-specific EPDs

- history: the manufacture of mats is in our DNA

Rinos is making use of Iso 9001:2015 as a Quality Management System. The policy declaration can be requested via our Customer Service desk.